Tutorial: High Speed Fiber Modulator Basics

Fiber intensity modulator : this tutorial provides an overview of the technical approaches most commonly used to change the amplitude (modulation) of laser light in the nanosecond or sub-nanosecond time domain in fiber-coupled laser systems.

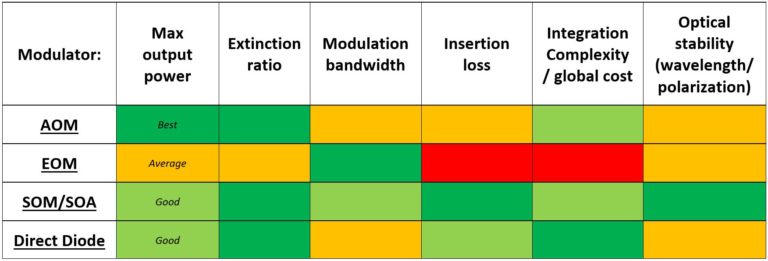

This tutorial gives a summary of the pros and cons of the four primary technical approaches to laser fiber-optic modulation. Three of these are based on external modulation : AOM (Acousto-Optic Modulators), EOM (Electro-Optic Modulators), SOA (Semiconductor Optical Amplifiers) and the fourth is by directly driving the laser diode.

Acousto-optics modulator : AOM

Acousto-optic fiber modulator devices are available at various wavelengths from 380 nm to 2500 nm. The major advantage of acousto-optic fiber coupled device modulation is the relatively high optical power these modulators can handle. They are specified to work with power levels which can reach several watts (more than 10 W in some cases). However, with acousto-optic modulators (AOM’s), a primary con is the trade off between the switching speed and the insertion loss. The more the optical beam is focused within the AOM’s embedded crystal, the faster it switches, but the more difficult it can reach the output fiber without suffering losses. For more information on this technology, you can read an in-depth overview of Acousto-optic Theory.

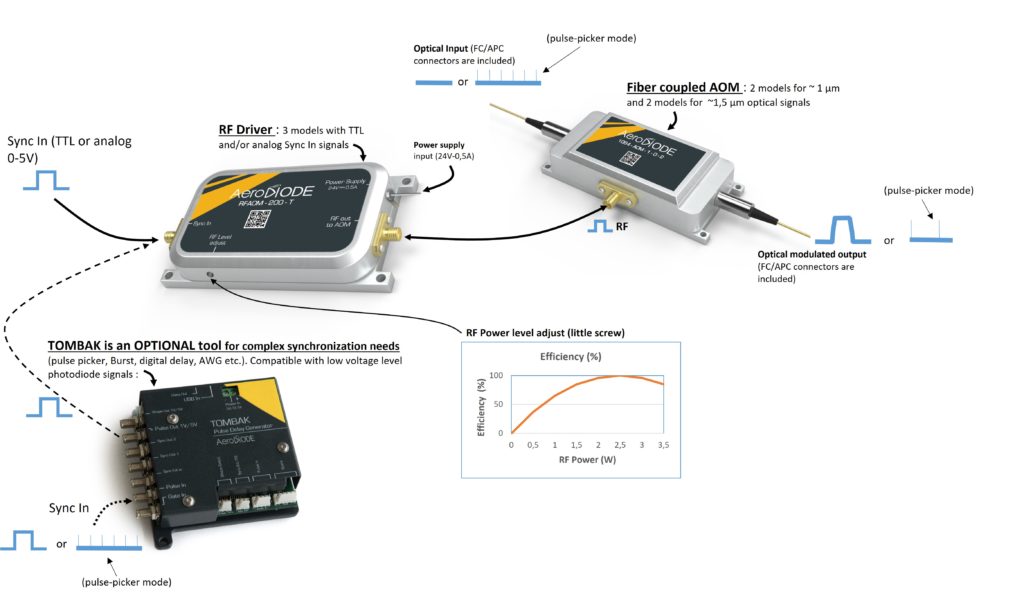

When considering the price of an AOM set-up, the user should consider the total cost of the three key elements:

- The AOM component itself

- The RF driver

- Eventually a fast switching synchronization electronics generating 0-1 V or 0-5 V depending on the RF driver

Wavelength (nm) | RF Frequency (MHz) | Max input power (W) | Rise time (ns) | Insertion Loss (dB) |

| 1000-1090 | 100 | 5 | 45 | 1.5 |

| 1000-1090 | 200 | 3 | 9.5 | 2.5 |

| 1520-1580 | 80 | 0.5 | 45 | 2.5 |

| 1520-1580 | 200 | 0.5 | 9.5 | 4.5 |

An example of multi-function, simple to use fast switching synchronization electronics module is shown in figure 4. This module is not mandatory but it combines an impressive number of functions for complex synchronization needs including pulse-picking and an AWG (Arbitrary Waveform Generator). This pulse delay generator is manufactured by AeroDIODE :

Electro-optics modulator : EOM

The major advantage of an electro-optic modulator (EOM) is their bandwidth, which extends into the 10’s of GHz range. Keep in mind that the user must find the driving electronics to support this bandwidth.

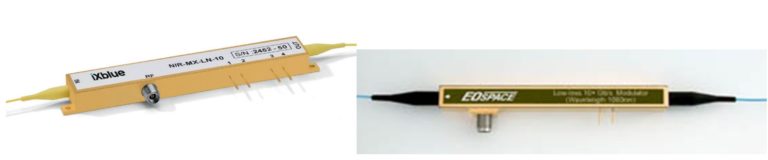

3 highly reputable manufacturers of EOM fiber modulators are:

Several difficulties which are associated with electro-optic modulator (EOM) can be solved by increasing the complexity of the overall setup. If you decide to utilize an EOM based modulation setup, there are several parameters which need to be considered and correctly managed:

- Insertion loss :

Insertion loss levels vary from one model to another. In general, improving one key performance attribute of an EOM (for example extinction ratio) can have a negative consequence on the insertion losses. Typical insertion losses are in the range of 4-5 dB.

- Maximum input/output power :

Typical maximum input power is in the range of 50 mW (17 dBm). This maximum power is generally an average power. One can thus overcome this limit / problem by applying a pulsed signal at the input fiber instead of a CW signal. The modulated input signal can be generated by an AOM (refer to AOM overview above) or by directly modulating the laser diode. This, however, produces some other difficulties associated with the stability of the V-bias of the EOM (see below).

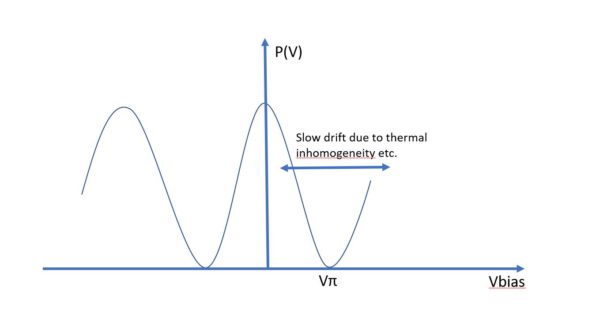

- Stability of V-bias :

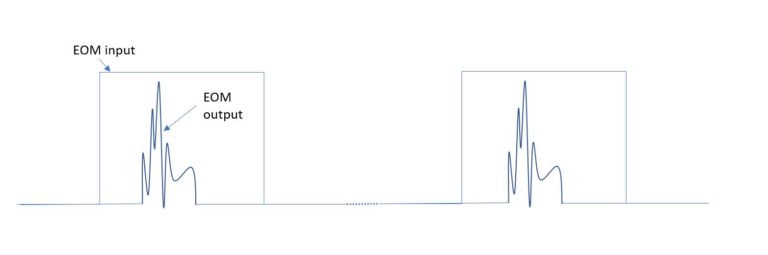

This is one of the most difficult technical issues to manage when using an EOM. EOM’s generally drift because of thermal inhomogeneity etc. This causes the transfer function (see Figure 6) to move in the horizontal direction and the modulation signal is applied to a changing operating point. This can affect the quality of the modulation.

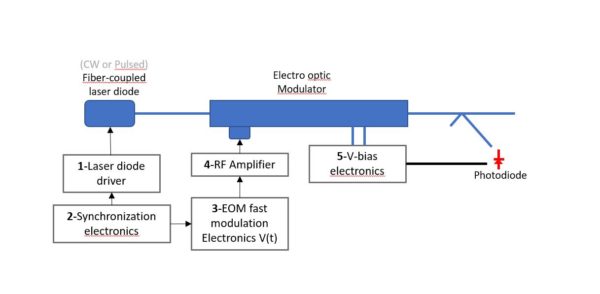

In order to operate the intensity modulator and obtain the desired modulation, the user must apply two separate voltages to the modulator: (1) A modulation voltage V(t) and (2) a DC voltage (also called V-bias). The bias voltage selects the desired operating point and compensates for the drift in order to keep more stable operating conditions.

Many suppliers offer the laser diode driver described in the block diagram above. Finding a pulser which generates stable, clean pulses in the nanosecond time domain is important. Here is an example of a well specified pulsed laser diode driver.

The product shown in Figure 4 can be efficiently used as a the second “synchronization” electronics source which is referred to in Figure 8.

Another AeroDIODE product worth mentioning combines the four first electronics functions of Figure 8 above with very good technical performance. See this link : high speed laser diode driver and Figure 10 below. This pulse driver is able to simultaneously drive and control a butterfly laser diode seeder in pulse or CW (#1), generate several synchronization signals (#2) drive the EOM with a programmable pulse shape with a temporal resolution down to 500 picoseconds (#3 and 4).

The fifth block shown in Figure 8 is very important when high stability is required (which is nearly always the case). Here are three products which are available from reputable manufacturers:

A major difficulty associated with the setup shown in Figure 7 occurs when a user needs to operate with a pulse regime at very low duty cycle. The low level of power might not be enough for the V-bias electronics to be able to keep control of the bias level. The difference between the electronics product generations plays an important role here.

Some examples of a few key technical parameters of EOM models available around 1064 nm and 1550 nm are shown in the table below :

| Wavelength (nm) | Bandwidth (GHz) | Extinction ratio (dB) | Insertion Loss (dB) |

| 1064 | 10 | 18 | 4.5 |

| 1064 (double) | 10 | 50 | 4.0 |

| 980-1150 | 12 | 30 | 3.5 |

| 1530 – 1625 | 12 | – | 3.5/2.7 |

| 1525 – 1605 | 14 | 20 | 4.0 |

Semiconductor Optical Modulator : SOM (SOA-based modulation)

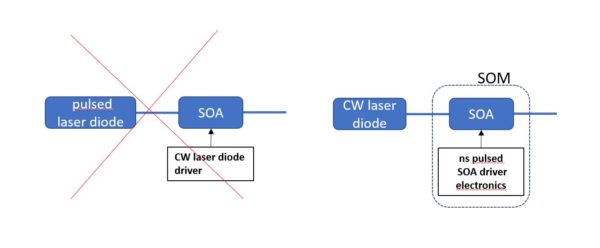

Semiconductor optical amplifiers (SOA) are a well-established alternative to CW EDFA’s (Erbium Doped Fiber Amplifiers) and are used to amplify a pulsed signal. A Semiconductor Optical Modulator (SOM) utilizes SOA technology in a different way than traditional SOA amplifiers have been used (Figure 10). Semiconductor optical modulation utilizes a SOA as a fiber modulator with potentially negative insertion loss (ie Gain). In this case, a CW laser diode signal is applied to the SOA and it is the level of current driving the SOA which is switched ON/OFF at GHz speed. This modulated signal can also be customized and shaped to accommodate many emerging applications.

There is a number of advantages to use SOA compared with other solutions :

- The dynamic range of an SOM is generally higher than that of an EOM or an AOM. For example, EOMs are often limited to < 30 dB, and often less since there is a strong polarization dependency.

- An SOM has no polarization rotation dependencies, whereas both an EOM and an AOM typically are susceptible to polarization dependencies.

- The spectrum of an SOM remains the same along the entire pulse, whereas when directly pulsing a laser diode, the user must consider the undesirable spectral effects which can occur from coupling of the frequency/phase spectrum and intensity profile.

One needs, however, to pay attention at three important characteristics :

- With PM SOAs, the high extinction ratio is polarization dependent and it is often necessary to add a polarizer (generally an isolator for its polarizing properties) at the output to reach the very high extinction ratio levels.

- SOA technologies can be very different from one supplier to another. A key parameter is the reflection level of the output part which can stimulate some laser operation in some cases. An isolator is often required between the input laser diode and the SOA.

- Depending on the configuration and input laser diode power, one may want to take advantage of the ability of the SOA to amplify the input signal. This is potentially interesting but this also can generate a small ASE signal. An ASE filter might be relevant in some integration configuration.

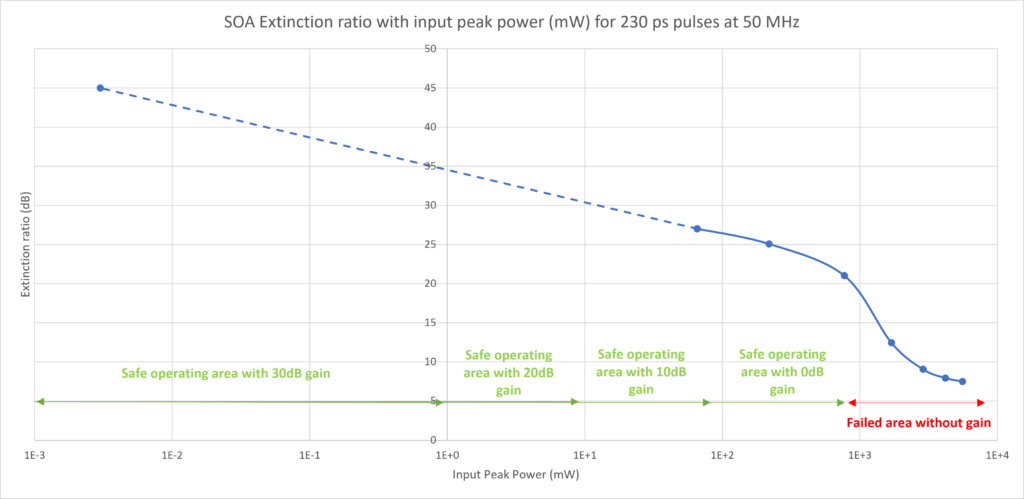

When using an SOM, extinction ratios as high as 70 dB are possible. The maximum input power is generally not much higher than the saturation output of typically 50 mW (17 dBm).

When a very high extinction ratio is required, the best choice is to use a PM SOA (with the relevant optimized driver) and use the amplification properties of the SOA. This way the low power applied and the absorption of the SOA makes the light reach pW levels when there is no current applied whereas it can reach, say, 100 mW when applying the nominal current, ie >80 dB extinction between “On” and “Off” regimes. The extinction ratio is even improved by adding an isolator after he SOA which block the fast axis remnant light.

AeroDIODE offers three models of open-frame Pulsed SOA driver and control module which are compatible with the pin configurations and the package size of most commercially available SOA’s. See this link : SOA pulsed driver

AeroDIODE offers also 3 complete SOM fiber optic modulator turn-key solutions. These SOM are offered with a broad selection of SOA’s from 775 nm to 1625 nm. Current and temperature control circuits and safety limits are pre-set and optimized to ensure the highest level of performance in pulsed mode. See this link : fiber optic modulator.

It is interesting to note that an SOA can also be used as, for example, a pulse picker. But one should know the limitation of this solution linked with the level of energy/peak power of the incoming pulse.

Direct laser diode modulation

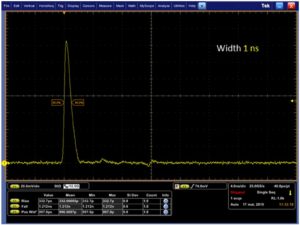

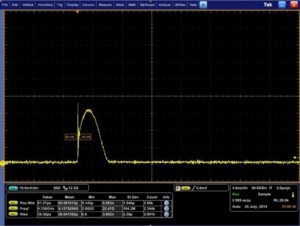

The last (but not least) solution for modulating the light coming from a fiber-coupled laser diode is to apply a direct modulation using a pulse control electronics current driver. An example of a 3 nanosecond pulse width is shown below. One can see the gain switch peak at the beginning of the pulse. This is a relaxation of the carriers within the laser diode. Gain switch peaks can be useful if one wants to isolate this gain switch peak pulse and get ~ 100 picosecond pulses. But the gain switch peak is typically an undesired property.

There are few companies around the world who specialize in manufacturing commercially available laser diode pulse drivers. However, the pulse shape at a short pulse width and the rise/fall time and Jitter levels can be very different from manufacturer to manufacturer. Also, there are many key features and additional functions which vary from each manufacturer, and ease of use should also be considered.

The bandwidth limitations are a result of the speed of the electronics on the “driver side” and the inductance of the laser diode on the other side. Reaching a 5 nanosecond per amp rise/fall time is possible in an ON/OFF switching mode from many suppliers. However, combining modularity, ease of use and high performance levels is the most difficult part when developing a pulsed driver.

AeroDIODE offers four ON/OFF laser diode switching driver models with switching speed from 3 ns/A to less than 0.5 ns/A. Another high speed laser diode driver product, also offered by AeroDIODE for direct laser diode modulation, is called a “Pulse-Shaper”. It is the same product shown Figure 10, but configured for direct laser diode current shaping. It includes an internal AWG and is able to shape the laser diode output with 48 dB amplitude resolution and 500 picoseconds of timing resolution. See this link : high speed laser diode driver.

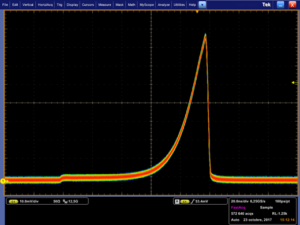

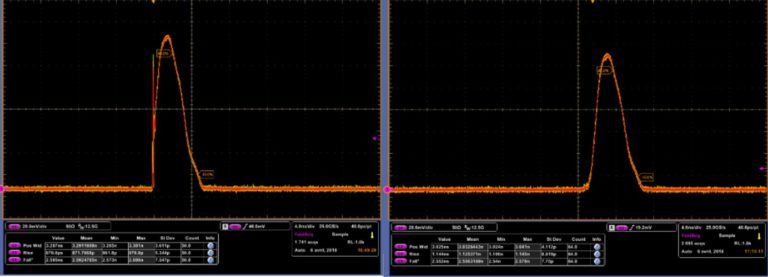

This pulse-shaper module allows the user to program a customized shape with a high bandwidth AWG and generates the desired custom optical pulse shape. As seen in the figure below, this module also has a special internal function which allows the user to mitigate the gain switch peak :

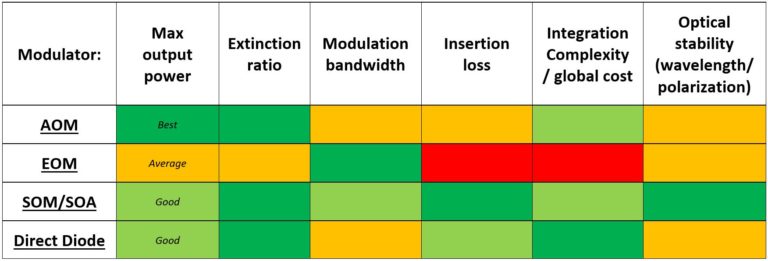

Conclusion

The table below summarizes the pros and the cons of the various solutions. AOMs are interesting when looking for several Watts of output power. EOMs are the fastest solutions despite a high level of integration complexity, low extinction ratio and high insertion loss. SOM (i.e. SOA used in a modulator configuration with a special electronics) has clearly major advantages when looking for a cost-effective GHz speed solution. Direct laser diode is the cheapest solution but be careful that the wavelength shifts all along the pulse and one needs to choose the good driving electronics to reach a minimum peak power when looking for less than 10 ns pulse width.